Risk assessment for ITER Korea

South Korea

The ITER project has adopted the RAMI (Reliability, Availability, Maintainability and Inspectability) approach to technical risk control to guide the design of components in preparation for operation and maintenance. This approach helps to improve the safety and reliable operation of key systems needed to achieve one of ITER’s objectives, to test tritium breeding.

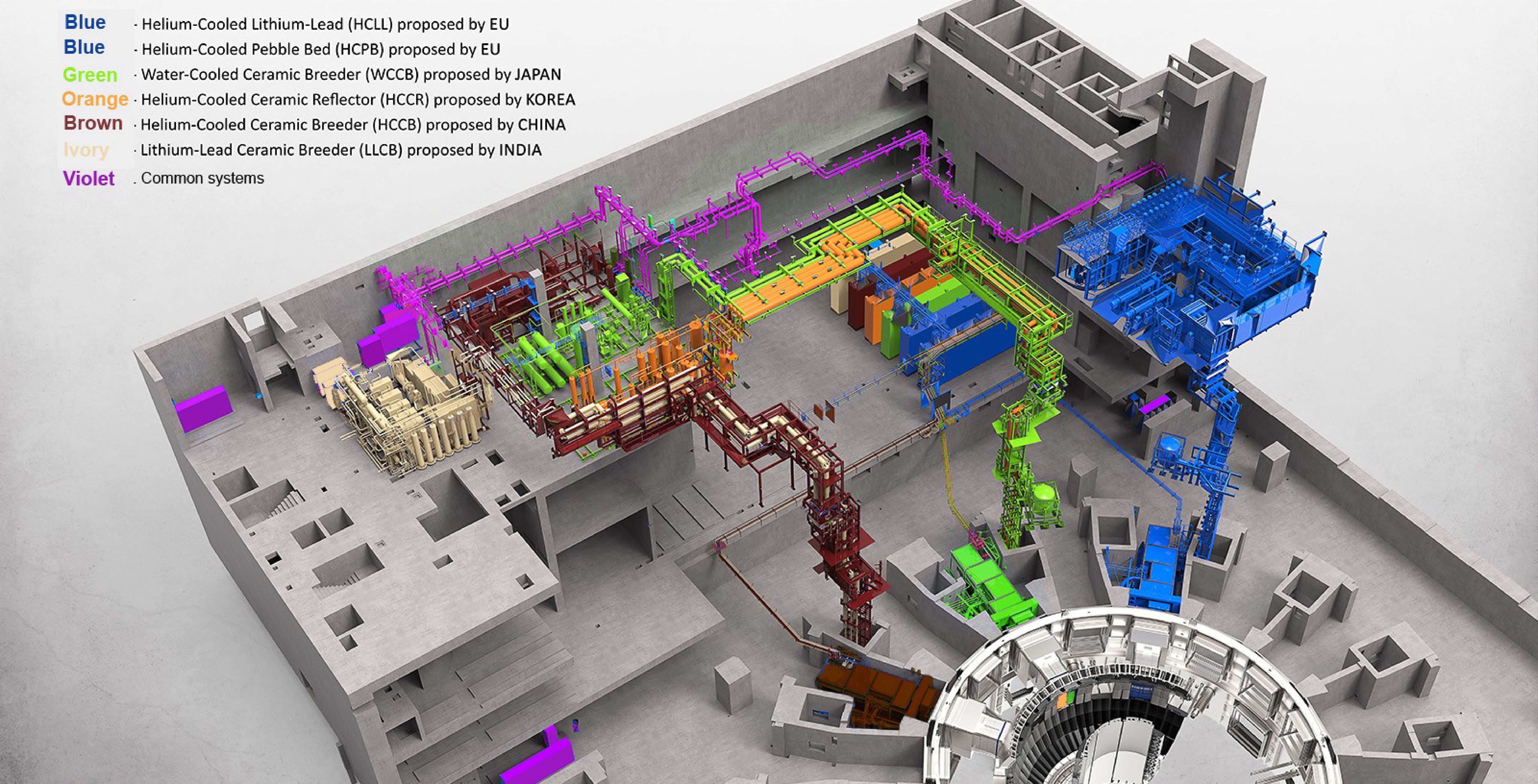

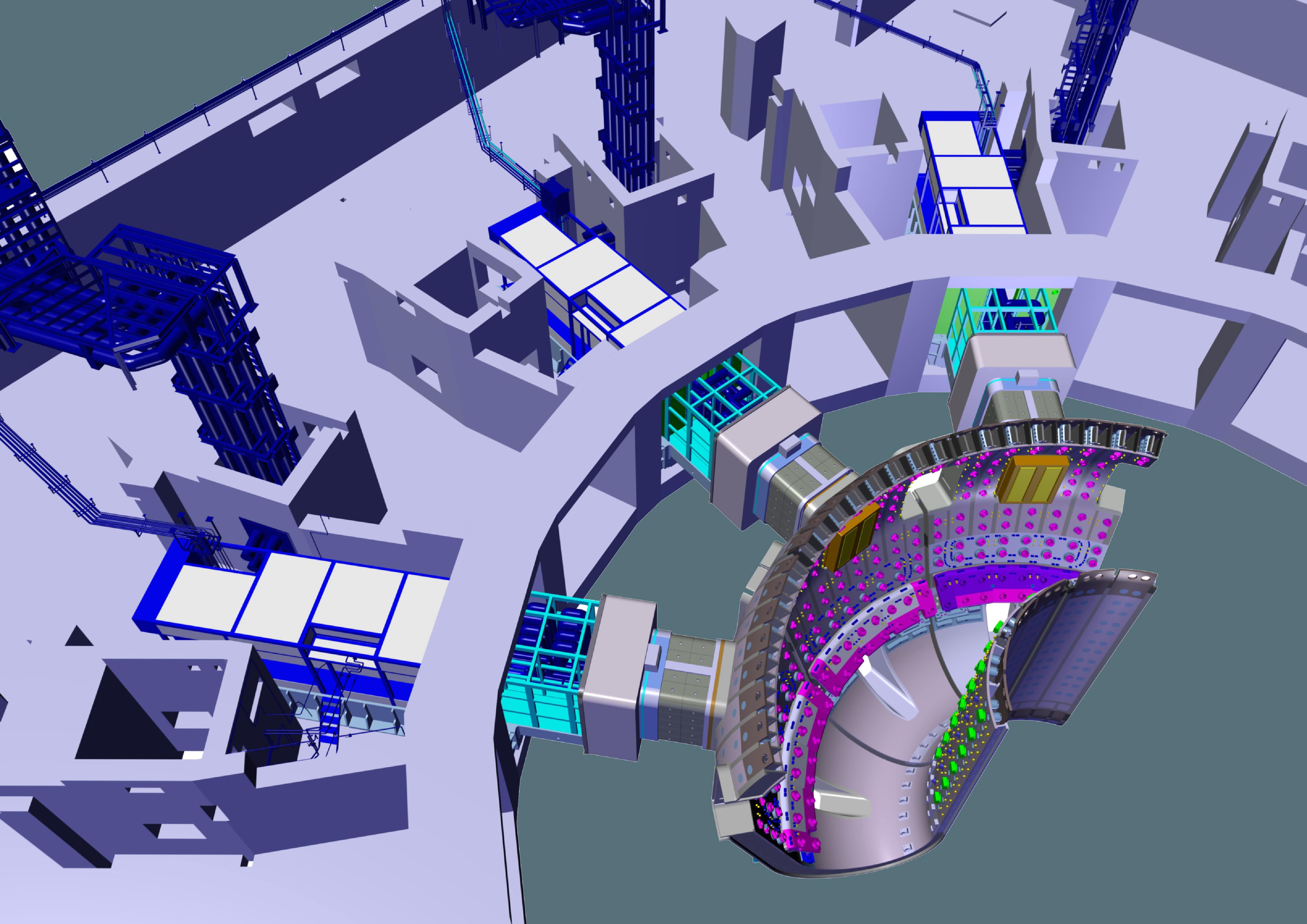

In 2012, IDOM began the RAMI analysis for two subsystems of the TBM Program, a key system for the operation of the ITER machine. One of the main objectives of the TBMs is to ensure self-sufficient production of tritium, a hydrogen isotope, which is the fuel for fusion reactions.

During 2023, IDOM carried out the RAMI analysis for three other TBM subsystems that play a major role in the development of the ITER project. They must therefore be reliable and available for uninterrupted operation:

- The Neutron Activation System is responsible for measuring the absolute neutron fluence and the absolute neutron flux with information on the neutron spectrum at selected positions of the TBM.

- The Helium Coolant System whose main function is to remove heat by means of helium circulating in cooling ducts embedded in the first wall and in the cooling and stiffening plates of the breeding units.

- The Coolant Purification System will be used to remove the tritium that has penetrated from the TBM into the HCS and to control the chemistry of the primary coolant in the HCS.

RAMI analyses are used to identify the most critical components and propose mitigation actions to reduce their severity. These include (1) proposals for design changes (at component, system, or technology level), (2) maintenance activities or (3) changes in the operation of the system.

The following are the phases of the project developed by IDOM for ITER Korea:

- Understanding the system operation: reviewing technical documentation such as system description, drawings, and 3D models, and through functional analysis, identifying the main function and its components.

- For each component, every failure was evaluated using Failure Modes, Effects and Criticality Analysis (FMECA). Depending on the local and global consequences, IDOM refined the testing and maintenance procedures, providing preventive and predictive activities to reduce the impact of this failure on the system and the ITER machine facility.

- Taking these results into account, IDOM modeled and simulated the system in blocks and obtained an availability result. IDOM proposed a list of spare parts, optimizing their quantity and the strategy for their acquisition.